Induction Hardening

What is Induction Hardening?

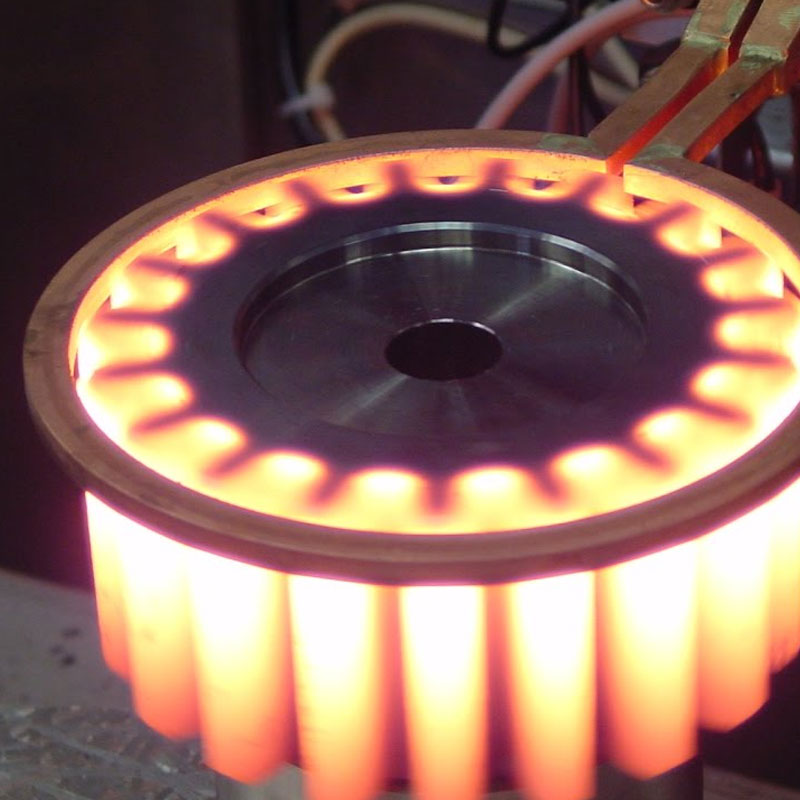

Induction hardening is a method used for the surface hardening of steel and other alloy components. The components to be heat treated are placed inside a copper coil and then heated above their transformation temperature by applying an AC to the coil. The AC current in the coil produces an alternating magnetic field within the workpiece which causes the outer surface of the part to heat to a temperature above the transformation range. The parts were then followed by immediate quenching. Induction hardening is an electromagnetic procedure using a copper inductor coil, which is fed a current at a specific frequency and power level. Hardening process is utilised to increase surface hardness, wear resistance, and fatigue life through formation of a hardened surface layer while maintaining an unaffected core microstructure. Induction hardening is exceptional at restoring field failures, improvements in strength, fatigue and wear resistance in a localised area without having to redesign the component.

Advantages of Induction Hardening

Induction Hardening is done for components that are exposed to heavy loading as it gives high surface hardness with a deep case capable of handling enormously high loads. Fatigue strength is also increased by the creation of a soft core surrounded by a tremendously tough outer layer. These properties are needed for components that are subject to torsional loading and surfaces that experience impact forces.

Application & materials

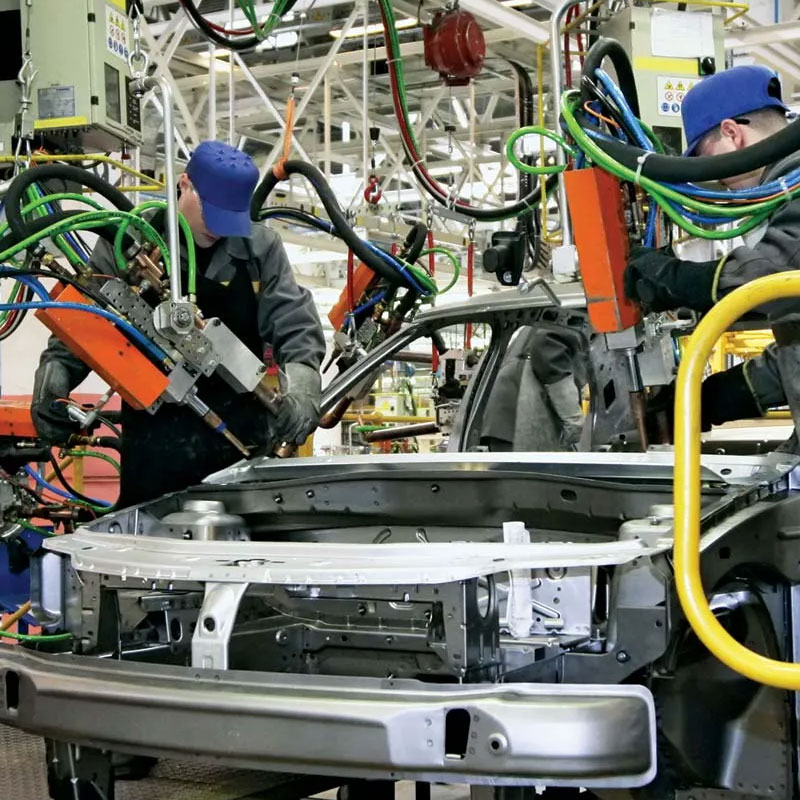

Induction hardening finds applications include suspension, powertrain, engine components and stampings, gears, cam lobes, shafts, axles, stampings, and spindles, mostly symmetrical parts.

Induction Heaters Products

Induction Heaters by Ratings

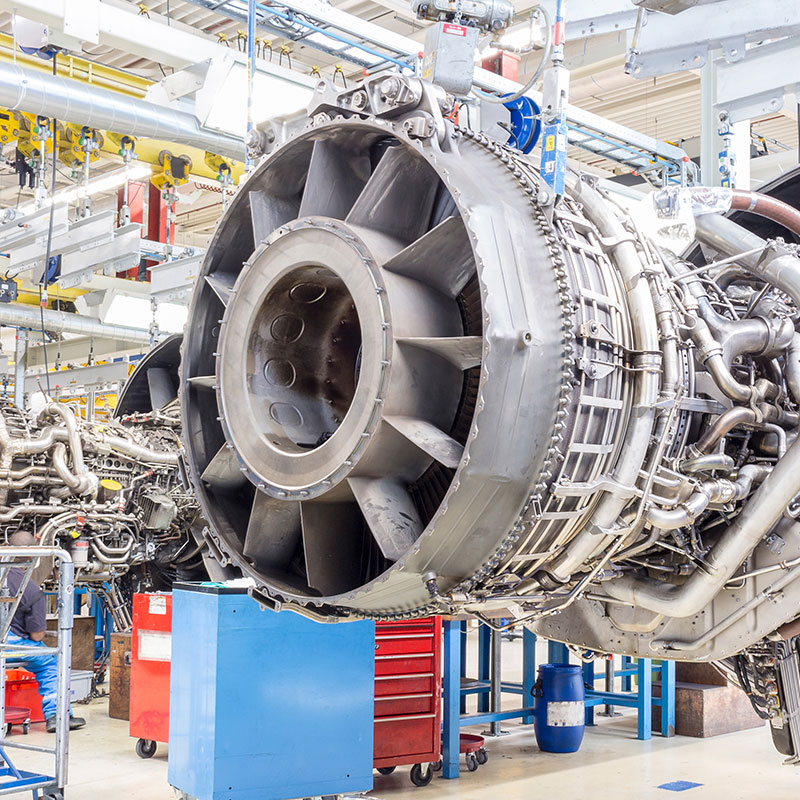

In Aviation Industry, product quality and process consistency are obviously crucial. Precise, repeatable and contact-free induction heating is crucial for aircraft manufacturers, and their suppliers. Our compact Induction Heaters are chiefly sought after by maintenance divisions because of their ease of mobility…. Read More

Induction heaters are widely used for food and beverage processing for applications such as drying & dehydrating, sanitation & disinfection, pasteurization, baking, etc on industrial scales. Induction heating is completed using a process called susceptor heating which consists of using an induction coil to heat an electrically …. Read More

Induction heating provides a faster, superior substitute to furnace heating and more efficiently heating in forging applications. Induction heating has high power density, exceptionally rapid heating, with exacting control over the heated area. Precision Instruments & Allieds’ Induction Heaters Induction heating technology…. Read More

Precision Instruments & Allieds’ supplies Induction Heaters to the world’s leading producers of freezers, refrigerators, dishwashers, washing machines and faucets. Induction heaters are used for induction heating for controllable, accurate, and repeatable, leak-proof and corrosion-resistant joints. …. Read More

Induction heating provides quick, reliable heat for the medical devices manufacturing industry and research applications. Induction Heaters are widely used in the medical device manufacturing industry for applications like catheter tipping, annealing steel tubes, brazing miniature parts, curing…. Read More

Dies and Moulds are used in numerous manufacturing procedures and in several situations the process would require induction heating. The procedure of injection molding of plastic or rubber products needs pre-heating of the molds to a higher temperature, to confirm the proper flow…. Read More

Precision Instruments & Allieds’ Induction Heaters Induction heating has been serving oil and gas service companies and is used within a variety of fields in the oil and gas industry. Induction Heaters are widely used in Oil & Gas Industry for applications like pre weld heat treatment, post weld heat treatment…. Read More

Precision Instruments & Allieds’ is the leading supplier of heating solutions for the power generation industry and energy sector. Induction Heaters are widely used in the Power Generation Industry for applications like production of gears and slewing rings for wind turbines, industrial gas turbine engine…. Read More

In Railways, Induction Heaters are widely used for crucial tasks in the manufacture and maintenance of rolling stock and rails and are chiefly sought after because of their ease of mobility and flexibility. Induction Heaters are widely used in railways for shrink-fitting of ball bearings, lock rings, steel tyres on rims…. Read More

Induction heaters are extensively used in shipyards for the construction, repair and maintenance of all kinds of vessels and are chiefly sought after because of their ease of mobility and flexibility. Induction Heaters are widely used in heat treatment of shafts, straight welding of beams in double hulls…. Read More

Induction heating has outstanding reliability, efficiency and robustness. Induction Heaters are widely used in Tube & Pipes Manufacturing Industry for applications like preheating and post heating of various work pieces, Preheating and stress relieving of OCTG pipe ends, Seam annealing of longitudinal tube welds…. Read More