Induction Mounting and Dismounting

What is Induction Mounting and Dismounting?

Bearings are machine part in which a shaft rotates, designed to diminish the friction between different parts and is subdivided into different types according to their shape or direction of motion like tapered roller bearings, spherical roller bearings, needle roller bearings and cylindrical roller bearings. Induction heating is a safe, non-contact method for accurately heating electrically conductive materials, such as bearings. Bearing induction heating allows properly fit bearings onto a shaft. The induction heating produces an oscillating electrical current that causes the bearing or metal to heat when placed in the device’s magnetic field.

Mounting bearings with induction heaters

Induction heaters are ultimate for mounting bearings as they allow them to preheat bearings to about 120 degrees C. After this you can easily mount the bearings on the shaft. During cooling, there is a strong shrink connection between the shaft and the bearing.

Dismounting bearings with induction heaters

Bearings have a restricted life span and therefore are required to be replaced every now and then. To do this, bearings are disassembled and the shrink connection is removed. To attain this, only the ball bearings are used and induction heating is used and not the shaft itself.

Advantages of Induction Heating

- Decreases bearing damage and Increases bearing lifecycle.

- Cost-effective and safer to use.

- Easy to operate and set up.

- Simplifies temperature monitoring and control.

- Supports fast, repeatable, and controllable results.

Induction Heaters Products

Induction Heaters by Ratings

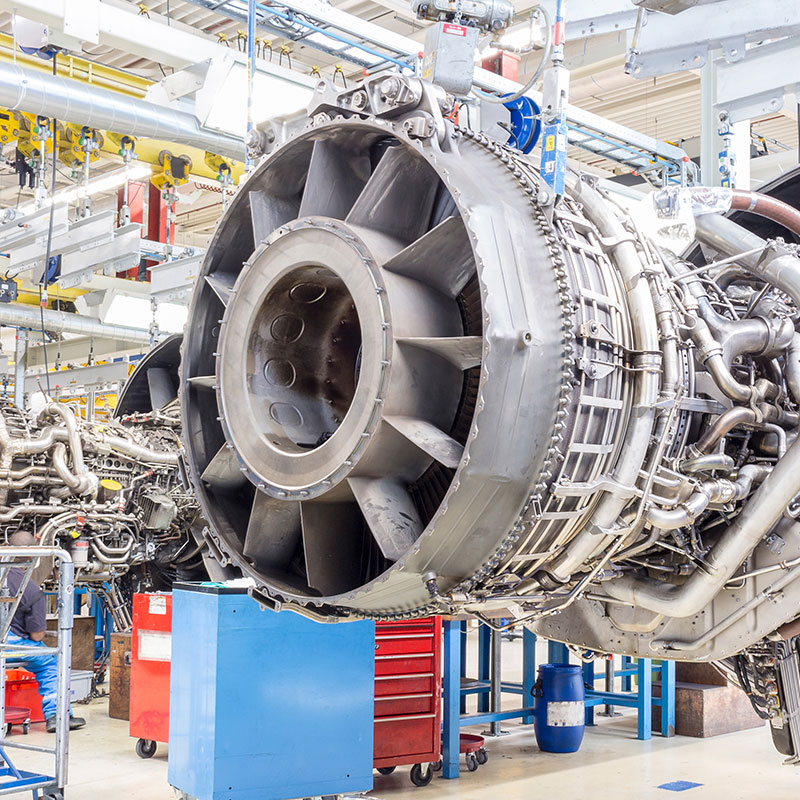

In Aviation Industry, product quality and process consistency are obviously crucial. Precise, repeatable and contact-free induction heating is crucial for aircraft manufacturers, and their suppliers. Our compact Induction Heaters are chiefly sought after by maintenance divisions because of their ease of mobility…. Read More

Induction heaters are widely used for food and beverage processing for applications such as drying & dehydrating, sanitation & disinfection, pasteurization, baking, etc on industrial scales. Induction heating is completed using a process called susceptor heating which consists of using an induction coil to heat an electrically …. Read More

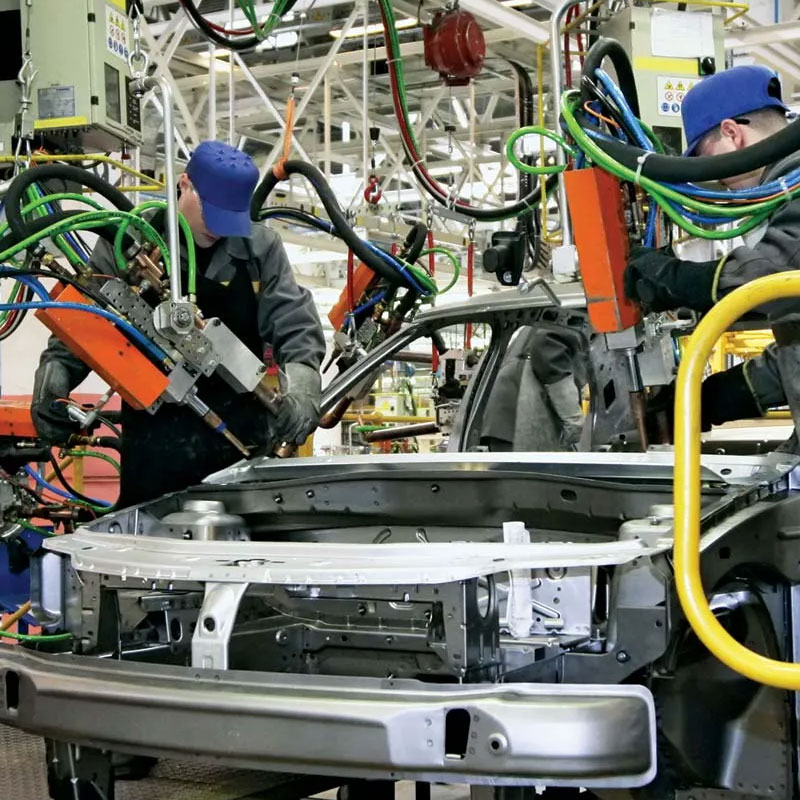

Induction heating provides a faster, superior substitute to furnace heating and more efficiently heating in forging applications. Induction heating has high power density, exceptionally rapid heating, with exacting control over the heated area. Precision Instruments & Allieds’ Induction Heaters Induction heating technology…. Read More

Precision Instruments & Allieds’ supplies Induction Heaters to the world’s leading producers of freezers, refrigerators, dishwashers, washing machines and faucets. Induction heaters are used for induction heating for controllable, accurate, and repeatable, leak-proof and corrosion-resistant joints. …. Read More

Induction heating provides quick, reliable heat for the medical devices manufacturing industry and research applications. Induction Heaters are widely used in the medical device manufacturing industry for applications like catheter tipping, annealing steel tubes, brazing miniature parts, curing…. Read More

Dies and Moulds are used in numerous manufacturing procedures and in several situations the process would require induction heating. The procedure of injection molding of plastic or rubber products needs pre-heating of the molds to a higher temperature, to confirm the proper flow…. Read More

Precision Instruments & Allieds’ Induction Heaters Induction heating has been serving oil and gas service companies and is used within a variety of fields in the oil and gas industry. Induction Heaters are widely used in Oil & Gas Industry for applications like pre weld heat treatment, post weld heat treatment…. Read More

Precision Instruments & Allieds’ is the leading supplier of heating solutions for the power generation industry and energy sector. Induction Heaters are widely used in the Power Generation Industry for applications like production of gears and slewing rings for wind turbines, industrial gas turbine engine…. Read More

In Railways, Induction Heaters are widely used for crucial tasks in the manufacture and maintenance of rolling stock and rails and are chiefly sought after because of their ease of mobility and flexibility. Induction Heaters are widely used in railways for shrink-fitting of ball bearings, lock rings, steel tyres on rims…. Read More

Induction heaters are extensively used in shipyards for the construction, repair and maintenance of all kinds of vessels and are chiefly sought after because of their ease of mobility and flexibility. Induction Heaters are widely used in heat treatment of shafts, straight welding of beams in double hulls…. Read More

Induction heating has outstanding reliability, efficiency and robustness. Induction Heaters are widely used in Tube & Pipes Manufacturing Industry for applications like preheating and post heating of various work pieces, Preheating and stress relieving of OCTG pipe ends, Seam annealing of longitudinal tube welds…. Read More